|

Loading...

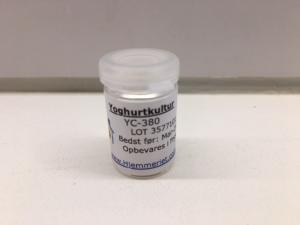

Contents: 0,5 g.

Contains the following:

| O | - Lactococcus lactis sp. cremoris | | D | - Lactococcus lactis sp. lactis biovar diacetylactis | | L | - Leuconostoc sp. mesenteroides |

| Culture properties: | | Structure | 3 | | | Taste giving | 3 | | | Gas production | 2 | | | Acidification speed | 3 | | | Post-acidification | 2 | | | | Scale: 0-None, 1-Low, 2-Moderate, 3-Middle, 4-High, 5-Very High |

This starter culture ferments any dairy milk or vegetable milk like soy or coconut as long as is contains adequate amounts of sugars for the bacteria to thrive.

It is also possible to make lactose-free soured milk products or yogurts from dairy. Learn how to make lactose free milk here.

Learn how to make your own home-made yogurt Learn how to make your own home-made yogurt

Chose a milk of your preference (skimmed, semi skimmed, full fat) even soy or coconut milk.

Since fat contents does not affect the fermentation process, full fat milk produces full fat yogurt, as will low fat milk produce low fat yogurt. To make high fat creamy yogurts - simply add in a bit of cream to the milk.

Making home made yogurt is very simple, just follow the steps below:

- In a pot, heat the milk to 42°C - use a thermometer to monitor the temperature

- Dissolve starter culture in to a small portion of the milk, mix in well and add this to the larger portion of milk.

- Place the pot in a warm place. It may be in an oven, in a boiler room wrapped in a warm blanket or in a yogurt maker.

- The most important thing is that the place maintains a constant 40-42°C throughout the fermentation process.

- Leave the yogurt to ferment for 6-12 hours.

- Then transfer the pot to the refrigerator and let it mature for another 12 hours.

- Hereafter the yogurt is ready for you to enjoy.

If you can not provide 42°C anywhere in your house, an electrical yogurt maker can be great tools to have as it sustains and ensures 42°C throughout the fermentation process - learn more.

When the yogurt is done and has matured in the fridge, you may take out a few table spoons of it, to use as starter culture for your next batch of yogurt. It will have the exact same types of bacteria as your first starter culture did.

This procedure can be repeated over and over again. However, bare in mind that contamination from unwanted bacteria may occure somewhere along the line which will shift both flavour and texture. If this happens, start over with a new starter culture and repeat the process.

Regular yogurts from stores may also serve as starter cultures, just make sure the ones you buy are fresh and has no additives. Use a few table spoons to culture the milk.

Dairy free milks like soy or coconut nut contains no lactose on which lactic acid bacteria love to thrive. They therefore tend to thrive less well on nutmilks compared to dairy. This can sometimes make theese yogurts less succesful and not well suited as starter cultures. Using freeze dried starter culture may therefore be necessary for each new batch you make.

Note: Nutmilks often produce thinner yogurts than dairy, so thickening agents may be useful. More info below.

As with any food, there is always a risk with contamination of unwanted bacteria from the surrounding environment. If they make their way in to the milk either from tools or air, they can sometimes multiply alongside the good bacteria. This will produce changes in flavors and texture - the more times you use "the new yogurt" to culture the next portion of milk, the greater the risk. If contamination occurs, simply start over with a new freeze-dried culture or a fresh yogurt from the super market. Remember hygiene is crucial, make sure to sterilise tools well and keep things clean.

The unique blend of bacteria in different starter cultures is what shapes texture and flavors in yogurts and make one yogurt different from another. If you are tempted to mix several starter cultures to maximize the number of species in the yogurt, you may therefore not necessarily get the great flavor and the texture you hoped for.

Learn how to influence texture and flavors in home-made yogurt Learn how to influence texture and flavors in home-made yogurt

While lots of people like regular yogurts, some prefer them rich and creamy and some like different flavourings.

Yogurts can be made thin as cream or thick as soured cream - depending on the type of milk you use. Here is a few tips on how to influence texture and flavors to your likings.

Adjust texture

- Pasteurized milk makes yogurt thicker.

Fresh unpasteurized milk usually produce thin yogurts compared to pasteurized milk. If you pasteurize milk right before adding starter culture, it will make a thicker yogurt. To pasteurize milk; heat to 72°C - 80°C. The longer milk is kept at this temperature (up to 30 minutes), the thicker these yogurt turns out. Cool it to 42°C before before culturing it with starter and begin fermentation.

Pasteurization causes a tiny break down in proteins and this is what enhances coagulation during fermentation.

- Use milk with a higher fat content.

The fat content is partly what makes them thick and creamy. Full fat milk produces a much thicker yogurt than skimmed milk. Using full fat cream or adding just some into the milk will enhance thickness and form a nice rich and delicious yogurt.

- Straining the yoghurt.

If you want to make yogurts thicker, not increasing the fat content - simply drain off excess whey. Place your freshy made and chilled yogurt in a colander lined with a fine cheesecloth or simply use a coffee filter. Leave the yogurt to drain off slowly - preferably in the refrigerator to avoid air contamination. Yogurts strainers are available here. Draining takes time - up to 1 day. Greek yogurt is made in this way. Any left over whey can serve as starter culture for fermented vegetables or for baking. Or you could freeze it for later use in smoothies and foods.

- Adding milk powder.

Protein coagulation is what causes milk to thicken and form the texture we know in yogurts and when adding a protein powder you will increase coagulation. Skimmed milk powder is an option. Make sure to mix in the milk powder before adding starter culture. Dissolve it in a small amount of water and add it to the milk. Rule of thumb, use ½ cup powdered milk to every 1 liter of milk.

- Adding in thickening agents.

Other thickening agents can be added to the milk prior to adding starter culture or after the milk has fermented - right before you transfer it to the fridge. Thickening agents are extremely useful if you make yogurts from nut milks. If you use the freshly made yogurt to culture another batch, make sure to take this portion out before you add in the thickening agent.

Gelatin: Use 1 teaspoon of gelatin powder per 1 liter of milk. Add gelatin powder to the milk once it has reached 42°C and mix in well. You will only see the effects of gelatin after fermentation and once the yogurt has matured in the fridge.

Agar: Use ½ teaspoon of agar per liter of milk. Heat agar with a little water and leave the mixture to cool before adding it to freshly made yogurt.

Guar gum: Use 1 teaspoon guar gum per liter of milk. Mix guar gum with a tiny bit of milk and add that into the larger portion of milk.

Altering flavors

Sourness in yogurts is affected by which starter culture was used and for how long it is left to ferment. There is a vast variety of cultures out there, each culture is unique and so is the resulting sourness. By shortening or extending fermentation time you can control the sourness - the longer it ferments the more sour it becomes.

Add whichever flavorings you like, it could be your favorite fruit and/or sugar but remember to take out a portion for starter culture first, if you need to.

Since yogurt is always sour, sweeteners are popular. Use anything from plain white sugar to dark muscovado sugar or stevia - experiment and search your favorite.

If you do not wish to add refined sugars, here are some alternatives :

- Raw or pasteurized honey

- Maple syrup

- Natural non-caloric sweeteners such as stevia or sukrin (erithrytol)

- Chemical sweeteners such as aspartame or saccharin

- Sweet ingredients such as jam, fruit juice or lemonade

You can even add extracts such as vanilla, almond or chocolate.

The non-sweet flavors to add would be mint, lemon juice, garlic and cucumber. In the Middle East, spices like saffron, cardamom and nutmeg are very popular.

Contents of 0,5 g is intended for 25 liter.

This is a DVS culture.

A starter culture is defined as either a DVS culture or a heirloom culture.

A DVS culture is designed to give a unique flavors and texture every time. These cultures are called Direct Vat Set cultures or just DVS cultures. If a DSV culture was your base to make a batch and you use some of this as starter culture for your next batch, it could cause an undesireable shift in flavors and textures. This happens when the balance between bacterial strains shifts and may be noticable already after the second batch. It is not a problem to use this first batch as starter for the next but you may find flavors and textures hereafter alter too much. If this happens for you, make a fresh start using a DVS starter.

A DVS culture starter makes up to 25 litres or 250 litres with some chance of reusing the freshly made product as starter culture for more batches. The amount of starter culture to add when making 1 liter is very little - just a few pinches. Store the remainder of the DVS culture in the freezer to retain its activity for many months.

A heirloom culture is designed to make 1 portion of 1-1½ litres. The bacterial composition in a heirloom culture is in balance and only alters slightly from batch to batch, making them a good choice if you want to take out fresh portion as starter culture for the next batch. However, bare in mind, freshness is crucial for any starter culture and you may not always want to make new batches continuously. If so, simply freeze a small portion of the product for later use. Be aware; a defrosted product tend to be less active as starter culture and that poses a risk for changes in flavors and texture.

In sum, each type (DVS vs. heirloom) approximately yields the same amount but a DVS culture is much more convienient if you wish to make a product on occasion and have a break in between batches. DVS cultures barely looses any freshness in the freezer compared to a heirloom culture.

Our cultures come in 3 variations / sizes

- (Starter) cultures intended for 1 litre (small, silver sachet)

This is a heirloom culture.

It is 1 sachet, and you use the whole content to make your first litre of yogurt.

You will then use 1 tbls of this yoghurt as a starter for the next batch.

And you will use 1 tbls of each batch as a starter for the next batch.

- Cultures intended for 25 litre (small vials, with snap-cap closure)

This is a DVS-culture.

This is a small vial, and you need to use a "pinch" from the vial for each litre of yogurt you make.

You will eat the whole portion.

When you have to start making your next batch, you will sttart by using fresh culture from the vial.

It is perfectly possible to make a new batch by using a small portion of the previous batch, but you will likely observe that the structure and taste will rapidly change.

If you make 1 litre per batch, you will then be able to produce 25 batches.

- Cultures intended for 250 litre (en large sachet).

This is a DVS-culture.

This is a large portion (x 10) of the culture, intended for 25 litre.

Same procedure as described under 2.

If you make 1 litre per batch, you will then be able to produce 250 batches.

Note om dosering af bakteriekulturer og enzymer

Dosering af bakteriekulturer

Når man giver aktive mælkesyrebakterier de rette vækstbetingelser, dvs. vand, sukker/laktose og den rette temperatur, vil bakterierne formere sig med en hastighed så antallet af mælkesyrebakterier fordobles på cirka ½ time. Bakterierne omsætter sukkeret og vandet til energi og syre, som medfører at væsken bliver mere syrlig i takt med at antallet af bakterier stiger. Når antallet af bakterier efter nogle timer er vokset, er syrligheden af væsken øget, hvilket bevirker at aktiviteten af bakterierne falder. Syrligheden af væsken bliver til sidst så høj at bakterierne ikke længere trives og bakteriernes aktivitet stopper. Som følge af bakteriernes reducerede aktivitet, i takt med øget syrlighed, vil mængden af bakterier som man doserer ved f.eks. opstart af yoghurt eller ostefremstilling ikke være af afgørende betydning for syrningsforløbet. Vores opskrifter angiver ofte doseringen af bakteriekulturer i mængder af ”knivspidse”, hvilket ikke er et præcist mål, blot et udtryk for at der ikke skal bruges ret meget. Som forklaret ovenfor, hvis man laver 2 portioner og doserer dobbelt så meget kultur i den ene som i den anden vil resultatet blot være at den med mindst mængde starterkultur skal syrne ½ time længere end den anden. Man kan derfor udmærket ”strække” forbruget af kultur. Hvis en portion er angivet til at kunne række til 25 liter yoghurt, kan den fint række til mere, hvis man doserer mindre per liter og samtidig blot forlænger syrningstiden en anelse.

Doseringen af enzymer

Enzymer som osteløbe, lipase og laktase er proteiner, som har en kompleks struktur, der har den effekt at hvis enzymet rammer ind i et kaseinmolekyle (for osteløbe), et fedtstofmolekyle (for lipase) eller et laktosemolekyle (for laktase), så brydes kaseinet/fedtstoffet/laktosen op. Efter sammenstødet flyder enzymet uændret videre, rammer ind i flere andre molekyler og fortsætter således nedbrydningen.

Et enzym er ikke en organisme som formerer sig som en mælkesyrebakterie – enzymets effekt er udelukkende en følge af de tilfældige sammenstød af molekylerne. Jo flere sammenstød der sker, des hurtigere går processen og doseringen af enzymet er derfor forholdsvis afgørende for om processen forløber indenfor den tid som procesforløbet gives.

Osteløbe: Hvis man doserer for lidt osteløbe, vil koaguleringen gå for langsomt og mælken vil ikke stivne som ventet. Doseres for meget osteløbe vil mælken stivne hurtigere, men overdosering kan give bitter eftersmag i osten. Osteløbens effekt er meget afhængig af pH og temperatur. Ved frisk mælk med pH på cirka 6,8 er den optimale temperatur 34°C. Ved syrnet mælk (pH 4-5,5) er osteløben mindre kritisk overfor temperaturen og der doseres typisk mindre osteløbe, hvis mælken er syrnet forinden (f.eks. ved friskost og mozzarella). Til de fleste typer at ost, doseres osteløbe med 1 ml per 5 liter mælk. Man kan dosere mindre osteløbe og kompensere ved at forlænge tiden for koagulering, hvilket også har den effekt, at der tilbageholdes mere vand i ostemassen og osten bliver dermed blødere.

Laktase: For personer med intolerance overfor laktose, er det vigtigt at laktosen nedbrydes til simple sukkerstoffer, hvilket netop er laktasens effekt. Graden af intolerance er meget individuel. Nedbrydningen af laktosen tager den tid det tager, men doseringen er afgørende for denne tid. Doser efter anvisningen og brug den anviste tid, og inddrag personlige erfaringer. Laktasens effekt er meget afhængig af pH og temperatur. Dette er beskrevet nøjere under beskrivelsen af laktaseproduktet.

Lipase: Nedbrydningen af fedtstoffer giver smag i ost. Lipasens effekt er derfor ikke vigtig for at osten skabes, men lipasen er betydende for udviklingen af smag efter at osten er fremstillet. Vil du have en almindelig smagsudvikling, doseres lipasen efter anvisning, ellers doserer du mindre eller mere efter behag. Bemærk at man normalt kun tilsætter lipase til feta og blåskimmelost. Mikroorganismerne som man tilsætter til ostemælken, udvikler nemlig også lipase. For andre typer af ost end feta og blåskimmel, vil der blive skabt tilstrækkeligt af lipase gennem mikroorganismernes virke til at smagsudviklingen vil ske passende gennem modningstiden for osten.

Store in freezer (-18°C).

Om konsistens

Jo længere tid yoghurten syrnes, des mere tykflydende bliver den og des mere smag vil den tillige opnå.

Vil du opnå øget viskositet kan du varmebehandle mælken inden syrning.

Herunder ses et diagram, som illustrerer effekten af varmebehandling af mælk inden syrning,

på konsistensen (viskositeten) af tykmælk og yoghurt.

De farvede områder (1 – 5) afgrænser effekten af varmebehandlingen.

Område 5 giver den højeste viskositet, dvs. den mest tykflydende tykmælk/yoghurt.

Bemærk: Ændringen i viskositet ved varmebehandling skyldes påvirkning af mælkens valleproteiner.

Det betyder at effekten kun er til stede ved alm. mælk, dvs. IKKE ved plantebaserede produkter.

Diagrammet viser, er det mere er tiden end temperaturen, der giver en øget viskositet.

Der skal således en varmebehandlingstid på 10 min. eller mere,

og en temperatur på over 75°C for at opnå en høj viskositet.

Maksimal viskositet opnås ved varmebehandling i 17 minutter ved 87°C.

En nem måde at håndtere varmebehandlingen på er, at opvarme mælken til 85-90°C, slukke for varmen og lade gryden stå i f.eks. 10 minutter, inden gryden sættes i vandbad for hurtig afkøling til 42°C.

Diagrammet er kun vejledende og er udarbejdet på basis af tilgængeligt materiale fra

mejerisektoren (Karsten Bruun Qvist, Mejeribrugsinstituttet okt. 1987).

About fermented milk (yogurt/junket/sour cream)

For a fermented milk product to be traded as "yogurt" it must traditionally contain at least the two following bacterial species; Lactobacillus bulgaricus (or Lactobacillus delbrueckii subsp. bulgaricus) and Streptococcus termophilus (or Streptococcus salivarius subsp. thermophilus).

Fermented milk products that do not contain these species can not be marketed as yogurts, even though they often have the same properties as yogurt, in terms of flavor, texture and purpose. They are therefore often referred to as yogurts anyway - hence we speak off all fermented milk products as yogurt.

There is a vast variety of different starter cultures to choose from. All contain species of lactic acid bacteria and can be used with regular dairy milk or nut milks, such as soy or coconut milk.

Yogurt is cherished world wide and as a consequence there is a wide variation in flavor, texture and what bacteria that has been used to ferment the milk. The type of starter culture to choose depends solely on personal preference for flavors and texture.

Health benefits

Fermented milk products are thought to have many health benefits as lactic acid bacteria play a great role in keeping our digestive tract healty. When we consume fermented milk products, some of these bacteria make it to the gut and colonize our digestive system. They help break down food and perform many other health services. When we lack healthy bacteria in our digestive system, we are unable to break down the food properly and our overall health and digestive health can be compromized. By having a healthy gut flora we will not only feel good in your digestive tract - we will also feel more energized and our overall health improves as we benefit from the activities performed by the healthy bacteria.

Yogurt products with a high number of species are known as probiotics and are thought to be the healthiest. However, keep in mind it is not always a good idea to mix several starter culture to increase the probiotic content, as this may not get you great results in terms of flavor and texture. Different species have unique properties that could affect fermentation, flavor and texture. Some multiply at room temperature whilst other species prefer warmer temperatures, thus one will outnumber the other and some times throw the flavoring off.

Each species of lactic acid bacteria is thought to have their own unique health benefits, however Hjemmeriet has not the professional basis for recommending cultures nor specific bacteria if you wish to targets specific health benefits. We recommend that you seek information through the Internet or a professional health care nutritionist with knowledge about the health benefits of lactic acid bacteria. Although our personal opinion is that it it the healthiest to consume a variation of different fermented milk products, made with different strains of bacteria.

Thermophilic vs. Mesophilic lactic acid bacteria

Lactic acid bacteria are either thermophilic or mesophilic.

The term thermophilic means 'heat-loving'. These bacteria thrive best in warmer termperatures between 38-46°C which then must be provided for them to develop and fermentation to happen correctly. When making yogurt, 42°C is the optimal temperature. The yogurt starter culture is to be added to the luke warm milk and this temperature kept steady for appoximately 4-12 hours. This temperature can be maintained by using a yogurt maker, an oven, kept close to the stove, wrapped up under the bed sheets or in an insulated box. The most commonly know yogurts are Bulgarian, Greek and Acidophilus.

The mesophilic lactic acid bacteria thrive around 20-25°C, and ferments just by being left on the kitchen work top for 12-24 hours. Junkets and sour creams falls under this category.

Since the mesophilic cultures ferment at room temperature, these are somewhat easier to make but with the help of yogurt makers, ovens etc., the thermophilic cultures can be just as easy.

Both types benefit equally in maturing another 12 hours in the frigde, this will enhance better flavors and textures.

Homo - and hetero-fermenting bacterial strains

The bacteria in yogurts convert sugars in milk (mainly lactose) into lactic acid (C3H6O3), thereby raising acidity levels in the milk. Simply because the sugars provide them with the energy they need to thrive and reproduce.

Despite the fact that all species produce lactic acid, they differ in demand for certain conditions as they perform different activities. Some species produce lactic acid only - these are called homofermative. Yet, other species produce CO2 and flavoring substances (Acetyl, Acetaldehyde, and Ethanol) which is what flavors yogurt. These bacteria are called heterofermative. To accomplish nice balanced flavors and textures, the right blend of bacteria is crucial.

DVS vs. Heirloom yogurt starter cultures

DVS (Direct Vat Set) starter cultures are freeze dried (powder) cultures, ready to mix with milk and ferment your first batch. If you ensure good hygiene, a small portion of the fresh yogurt can be taken out and used to culture the next batch. This can be done only a few times, then the composition of bacteria would have changed so much you will have to start over with frieze dried starter culture.

Fresh yogurts made from heirloom (reusable) starter cultures can be used repeatedly to culture the next batch. In theory, the composition of these cultures are such that they can be reproduced for an infinite number batches without altering the composition of bacteria. However, be aware of potential contamination from other bacteria and do not leave more than 4-5 days inbetween making new batches.

Flavor

The distinctive sour flavor in yogurts is due to the lactic acid bacteria activity. Flavors vary from slightly sour to distinct sharp acidic flavors. It highly depends on which bacteria you use to ferment, fermenting time and temperature. The longer it ferments the stonger the sourness.

Acidity is measured in pH units. The lower the pH, the more acidic. Fresh milk is about pH 6.8 but long fermentation time could develop pH leves around 4.

Texture

Yogurt can vary greatly in terms of thickness and texture. Depending on which starter culture you choose, what type of milk and how you ferment it - this will influence the texture.

The thinnest yogurt is "piimä". If piimä is made based on cream the result will be only slightly thickened yogurt and still be consumed with a straw. At the opposite end of the scale you will find Greek yogurts, sometimes with a thickness like mashed potatoes.

Yogurt can be grainy, stringy, creamy or gelatinous, it all depends on the cultures and how it is fermented.

Why does yogurt turn thick in texture?

In regular milk, the proteins are organized in clusters (micelles) which have a small electric (negative) charge. When two micelles collide in the fresh milk they will therefore repel from each other and will be evenly distributed in the milk.

When milk ferments, sugars are converted into lactic acid that are electrically positively charged. This interferes with the protein's movement as they are slightly negatively charged. The consequence is that the micelles will be more bound to their present position which will result in a thickening of the milk (liquid).

If you like thicker yogurts, heat the milk to 85°C prior to adding your culture, maintain this temperature for up to 30 minutes and cool the milk before adding culture and begin fermenting. This will affect proteins by hydrolyzation and thickens yogurt.

If you like even thicker texture, once fermentation is complete, drain of excess whey using a strainer, a colander lined with a cheese cloth or anything else suitable. It is a good idea to let it drain off while standing in the refrigerator to minimize the risk of contamination from unwanted bacteria.

Fresh cheese is drained yogurt...

Straining fresh yogurt produces a from of "Fresh Cheese". Remove excess whey as described above or you can also add a bit of rennet to thicken it. By adding a few drops of rennet, the proteins will tangle up in the presence of Calcium and cause a thickening. The whey will effortlessly separate from the proteins and easily be poured off.

For additional information - please see the following links: For additional information - please see the following links:

Use the following to understand your possibilities for choosing cultures and enzymes for the production of butter, soured milk or cream, yogurt and cheese.

Read the introductory explanations first. This explains the basics you need to understand the range of possibilities.

To make dairy products you typically need starter cultures and eventually enzymes and ripening cultures.

- Starter cultures contain good and healthy bacteria, typically lactic acid bacteria, which will ensure that the dairy product is acidified to give the product the desired taste and texture.

- Enzymes are proteins, like rennet to drain of whey or lipase to break down fats.

- Ripening cultures, when given the right conditions, will change texture and taste, like mould for brie cheese.

Bacteria strains used in starter cultures are classified based on their temperature for optimal growth:

- Mesophilic bacteria strains have an optimal growth at 20-25°C.

- Thermophilic bacteria strains have an optimal growth at 35-45°C.

A mesophilic starter culture contains mesophilic bacteria strains only.

A thermophilic starter culture contains thermophilic bacteria strains only.

A mix starter culture contains a blend of mesophilic and thermophilic bacteria strains.

In addition to the mesophilic/thermophilic classification, bacteria strains are divided into classes (O, D, L, T, Y, A and B), depending on specific properties of the bacteria strains. The O, D and L classes are mesophilic. The T, Y, A and B classes are thermophilic.

The starter culture tables show which bacteria strains each starter culture includes. Additional information is available for the starter cultures:

- Hover over the class symbol in the top row to see the names of bacterial strains for the class.

- Hover over the

symbol to display overall characteristics for the culture like flavour, structure and acid production speed. Where the symbol to display overall characteristics for the culture like flavour, structure and acid production speed. Where the  symbol is shown, this indicates that the culture is a heirloom culture, meaning that the starter culture is for fermenting a single portion of milk (used only for soured milk, creme fraiche or yogurt). Following batches can be cultured using a small portion of the previous batch. For non-heirloom cultures (also called DVS cultures), you will use a new portion of the culture each time. symbol is shown, this indicates that the culture is a heirloom culture, meaning that the starter culture is for fermenting a single portion of milk (used only for soured milk, creme fraiche or yogurt). Following batches can be cultured using a small portion of the previous batch. For non-heirloom cultures (also called DVS cultures), you will use a new portion of the culture each time.

- Hover over the

symbol to see the prices available for the culture. Clicking the symbol to see the prices available for the culture. Clicking the  symbol adds the specified amount to the cart. symbol adds the specified amount to the cart.

The starter cultures contain blends of bacteria strains depending on the style of the dairy product being made. Some of the cultures are shown to contain the same strains of bacteria; however, those cultures are not identical. They each have a different ratio, percentage or contains individual sub-spieces of strains in order to give the desired result.

Bacteria strains from class D and L are heterofermentive and will produce lactic acid along with CO2 (gas) and diacetyl and/or other components which will contribute a buttery taste. All other acidifying classes are homofermentive, producing only lactid acid and will contribute a more simple acidic taste.

For ripening cultures, proteolysis specifies in which degree the microorganisms breaks down the milk proteins, which contribute to the development of flavour and texture of the product.

Lipolysis specifies in which degree the microorganisms breaks down the milk fats, thereby contributing to the development of fatty acid flavour and texture of the product.

Om konsistens

Jo længere tid yoghurten syrnes, des mere tykflydende bliver den og des mere smag vil den tillige opnå.

Vil du opnå øget viskositet kan du varmebehandle mælken inden syrning.

Herunder ses et diagram, som illustrerer effekten af varmebehandling af mælk inden syrning,

på konsistensen (viskositeten) af tykmælk og yoghurt.

De farvede områder (1 – 5) afgrænser effekten af varmebehandlingen.

Område 5 giver den højeste viskositet, dvs. den mest tykflydende tykmælk/yoghurt.

Bemærk: Ændringen i viskositet ved varmebehandling skyldes påvirkning af mælkens valleproteiner.

Det betyder at effekten kun er til stede ved alm. mælk, dvs. IKKE ved plantebaserede produkter.

Diagrammet viser, er det mere er tiden end temperaturen, der giver en øget viskositet.

Der skal således en varmebehandlingstid på 10 min. eller mere,

og en temperatur på over 75°C for at opnå en høj viskositet.

Maksimal viskositet opnås ved varmebehandling i 17 minutter ved 87°C.

En nem måde at håndtere varmebehandlingen på er, at opvarme mælken til 85-90°C, slukke for varmen og lade gryden stå i f.eks. 10 minutter, inden gryden sættes i vandbad for hurtig afkøling til 42°C.

Diagrammet er kun vejledende og er udarbejdet på basis af tilgængeligt materiale fra

mejerisektoren (Karsten Bruun Qvist, Mejeribrugsinstituttet okt. 1987).

Current storage information:

Number of units in stock: 0

|

See Product Group

See Product Group

Temporarily out of stock

Temporarily out of stock

Learn how to make your own home-made yogurt

Learn how to make your own home-made yogurt

2/8

- Visitors: 1502153 - 1

2/8

- Visitors: 1502153 - 1