Webshop

My page

Learn more about making: Cheese

|

See How

Homemade cheeseCheese making is easy and not as difficult as you might think. If you have not tried it before, it may seem a bit overwhelming at first but... J Here is a little help for you J We have made some simple photo illustrations to help you understand how easy it is to make some of the most delicious cheeses at home – amongst them are Feta Cheese and Brie/Camembert. Click on the sections below to watch them. |

Feta

Feta Cheese – Photo illustrated recipeFeta Cheese is one of the most basic and simple cheeses to make at home. If you use fresh milk, good quality cultures and follow our recipe step by step - nothing should go wrong. The photo illustrations below will help you understand the process. Click here to open our standard Feta Cheese recipe with comments.

|

Ricotta

Ricotta – Photo illustrated recipeWhen you make Feta Cheese, Brie or many other types of cheeses, you end up with not only the cheese but quite a large portion of whey. Use some of it for baking tasty breads or rolls. This is the perfect ingredient since the lactic acid bacteria contributes with nice flavorings to the bread, whether it is made warm or cold risen. Apart from lactic acids, the whey even contains some left-over proteins from the cheese making process. When you ferment the whey and afterwards bring it close to a boil, these proteins will separate out and sink to the bottom. Run everything through a cheese cloth and you can indulge in some gorgeous homemade Ricotta too! Ricotta is a favorite ingredient in the Italian cuisine, in pasta-sauces, with spinach and herbs in tortellini and ravioli. Ricotta works deliciously in veggies pies too. It is a light cheese with its high-water content and the flavor is mild and slightly acidic. Below is a photo illustrated recipe on how to make ricotta, step by step. For this recipe, we used only whey but you can add extra milk or cream to the whey for a creamier and richer result.

|

||||||||||||||||||||||||||||||||

Brie and Camembert

Brie/Camembert – Photo illustrated recipeBy appearance and taste, a white mould cheese may seem like a complicated piece of art to create at home, but that is not the case. If you have already made feta cheese a few times, all it requires to make Brie or Camembert is a few small adjustments to the recipe and a little bit more patience. If you master making Feta cheese and know which adjustments to make, you will succeed in making delicious homemade Brie or Camembert. The greatest difference is the maturation. Feta cheese only takes two days to make where Brie and Camembert need 4-6 weeks to mature and develop while you patiently wait. White mould cheeses are easier to make than the blue mould cheeses. A white mould cheese only matures from the outside in, so to speak - while a blue moulded cheese matures from the inside out, as well as the outside in. When you master to make Brie or Camembert, the next step up is learning how to make blue mould cheeses – or rather the techniques to get blue moulds to develop correctly.

All other steps are the same, except from maturation which you will learn about below. The maturation process is very important for white mould cheeses, because this is what activates and causes the moulds to grow, given the right temperatures and humidity. Follow the illustrations below to learn more.

|

||||||||||||||||||||||||||||||||||||||||

Gorgonzola

Gorgonzola - Photo illustrated recipe

|

||||||||||||||||

|

This is our favorite thing to start with – a nice delicious gorgonzola, but there many other cheeses to choose from such as Saga, Danablue or Stilton. |

|

|

Scrape a tiny bit of the blue / greenish mold off and use it to inoculate the milk with according to our standard blue mold cheese recipe. |

|

|

If you followed our standard recipe for blue mold cheese, you should end up with cheeses looking like these - with an open structure. |

|

|

A close-up of what an opened structured cheese should look like. |

|

|

Mature the cheese in a thermo-box – see our photo illustrated guide on maturing Brie / Camembert to see how. |

|

|

After 10-14 days of maturation, the cheese is covered in green-blueish molds. |

|

|

..And the cheese is ready! If you do not fancy the outer appearance, simply scrape or wash the molds off. |

|

|

Why wait until tomorrow, for what you might enjoy today? |

|

Danbo

Danbo – Photo illustrated recipeDanbo is a hard cheese with little or no holes in its structure. We do not recommend it as a beginners cheese making project. However, if you are already experienced in making cheeses like Feta cheese or Brie – then Danbo could be the “next step” to take. Below is a photo illustrated recipe to help you understand each step in the process. How much you need of each ingredient depends on the mould size you wish to use. We used a large round mould with lid (from our web shop) for this recipe, plus the following ingredients and tools. Milk: 12 litres of whole milk (non-homogenized). Starter culture (freeze dried): 6-8 pinches – alternatively you could simply use 1-1½ dl fresh soured milk or butter milk as culture. Rennet: 3-4 ml. Salt: 500g. Tools from our standard cheese kit, plus cheese wax, cheese paper, a couple of buckets and extra cheese mats.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Markeder

Billedserie - Markeder

På markeder

og messer hvor vi deltager, viser vi hvor enkelt

Billedserien er

lavet i forbindelse med vores marked i Århus 2012 på

Tangkrogen hvor der tillige blev lavet en YouTube

video med titlen "Ost i lange baner" – mange tak

til Landzone.dk

|

|

|

|

Her er vores fine

stand på |

|

|

Det starter med

ganske almindelig mælk.

|

|

|

Efter ½ time tilsættes osteløbe, cirka 1 ml per 4 liter mælk. Læg låget på og håndklæde over for at temperaturen holdes bedst muligt.

|

|

|

Efter cirka ½

time er mælken koaguleret.

Gryden står

med låg og klæde over.

|

|

|

Ostemassen lægges nu op i osteforme som er placeret i en ostebakke med et fint ostenet i bunden. Man bruger et dørslag eller si for at flytte ostemassen fra gryden til osteformene. Endnu et ostenet og en ostebakke lægges ovenpå osteformene - bakken med bunden i vejret. Vallen vil fortsætte med at løbe fra ostemassen, gennem osteformenes huller i sider og bund og vallen ender dermed i ostebakken.

|

|

|

Når ostemassen har drænet og er vendt over cirka 1 døgn vil der ikke drænes mere valle fra ostemassen. Ved at starte ostefremstillingen en morgen, så vil dette stadie være nået den efterfølgende morgen. Afdræningen har medført at havde man startet med 6-7 liter sødmælk ville man få cirka 1 kg afdrænet ostemasse.

|

|

|

Den afdrænede

ostemasse lægges i saltlage i 2 – 8 timer afhængig

af smagspræferencer. |

|

|

Efter saltningen lægges osteklumperne i en lage af vindruekerneolie tilsat snittet hvidløg og laurbærblade. Alternativt kan osten lægges i en mild saltlage tilsat lidt valle og lidt calciumklorid. Der er fri mulighed for smagsprægning her – brug de krydderier som du ønsker. Beholderen med osten i lage placeres på køkkenbordet og der står den resten af dagen, så der tilsammen er gået cirka 2 døgn siden starten. |

|

|

Vil du lave brie/camembert eller gorgonzola er førløbet kun lidt anderledes: Starterkulturen ændres til en mælkesyrekultur som udover de almindelige mælkesyrebakterier også indeholder yoghurtkultur samt skimmelkultur. Gorgonzolakultur kan skaffes ved at man skraber lidt af den grønne kultur fra en god købt ost og tilsætter dette til mælken sammen med den øvrige starterkultur. Skimmelkultur til brie/camembert tilsættes mælken som frysetørret pulver.

|

|

|

Som biprodukt fra osteproduktionen kommer vallen – dvs. det vand som løb af ostemassen. Vallen indeholder gode mælkesyrebakterier og proteiner som er nyttige og som kan udnyttes på forskellig vis. Brug en lille smule til bagning: Vallens mælkesyrebakterier kan bidrage positivt til udviklingen af smag i hjemmebagt brød – særligt langtidshævet / koldhævet brød. Udskift vandet/mælken i opskriften med valle.

|

|

|

Fetaen er spiseklar

med det samme. Smagsprøverne gøres klar... Der er IKKE snydt noget sted. Det er så enkelt og bliver så lækkert.

Det svære for

os er at få budskabet ud. |

|

|

Her er vist de typiske typer af mælk vi anvender – Økologisk sødmælk fra Thise, Naturmælk, Irma eller Osted. Som nævnt tidligere kan man også bruge friskmalket mælk, hvis man er så heldig at komme i besiddelse af det. Syrevækkeren kan komme i form af lidt tykmælk eller kærnemælk. Eller bedre – meget lidt frysetørret mælkesyrebakterier. |

|

|

Her er et udvalg af hjemmeosterierne. De kommer i forskellige udgaver afhængig af ambitioner. |

|

|

Mange står længe og læser opskriften på feta. Den kan også findes under menuen Opskrifter på hjemmesiden sammen med mange andre opskrifter. |

|

Hvorfor vente til i morgen med hvad du kan have glæde af i dag ? |

|

|

|

|

About cheese

What is Cheese?Cheese is processed milk or better said - fermented or preserved milk. A process that roughly can be described as separating the liquid part of milk from its solids which leaves us with a substance we call cheese. The liquid (whey) part that is drained off also contains remains of what solids was in the milk. When the whey is heat-processed a special type of cheese can be made from it - whey cheese. |

Preface

ForewordTo make home-made cheese is quite simple. It only requires a few ingredients that are easily obtained, tools that are often close at hand in your kitchen and recipes that are easy to follow. Despite it is so simple to make cheese there are also elements to the cheese making process that involves a great deal of knowledge about the science behind the different processes. To every new cheese maker the process is mostly about learning through experience and get a sense of how to accomplish the best results and that is what makes cheese making into an art. When you first set out to make cheese you must know it takes time to learn the techniques and master the art of cheese making by getting a good sense of how the different processes work. If you use every experience in a constructive manner to improve your skills, you will be rewarded by the fun of making home-made cheese and the enjoyment it is to savour them. This document is meant to provide you with recipes that are easy to follow, lots of good advice and easy to understand explanations to every step in cheese the making process. This will guide you on what to do and how – but also why and let you in on the science behind the processes. When you know exactly what to do, when and why, you can ripe optimal results and combine that with your own creativity – cheese making will soon turn into art.

To make cheese in your own kitchen you need some equipment which is probably already in your kitchen – such as pots, bowls, colanders etc. The cheese making process can roughly be explained as the separation of the milk solids such as proteins, sugars, fats and minerals from the liquid part – whey. To make whey drainage easier, Hjemmeriet have developed a complete cheese kit that includes cheese trays, cheese mats, cheese moulds, thermometer, cultures and enzymes. This cheese kit contains practical tools that are very convenient when you make cheese but you can of cause make cheese at home simply by using your kitchen bowls, colanders and tea towels. It is not only great fun to make you own cheese but there are several reasons that speaks for advantages of making your own dairy products:

If you have any questions you are always welcome to contact us by phone (+45) 23 24 48 00 or write to us at Hjemmeriet@Hjemmeriet.com and we will get back to you as soon as possible. We also welcome you at our localities if you want visit our shop - check the opening hours on our website: https://Hjemmeriet.com |

A bit of history

The history of cheeseOur everyday lives surround us with things we think of as normal and yet know little of how they came to be, even if they often have some peculiar and interesting stories to tell - and cheese is no exception.

A vast number of books and articles have been written about cheese and if you were to read through some of them, you would most likely find many facts to surprise and enlighten you. Below is a short recap of some of the stories that can be found on the internet if you google the history of cheese: The first evidence of cows being milked and cheeses being made, date as far back as ancient times around 4.000-3.000 B.C. to the Sumerian civilization in south Mesopotamian (Iraq). It was the Sumerians that founded the first known urban civilization and with that followed domestication of animals. Before that, there existed only tribes of hunters and gatherers living of wild prey and what food they could gather. Every part of an animal was eaten or utilized by these hunters and gatherers, even the intestines which is thought to have been the first thing they would have relished in, as it was full of nutritious plants and substances.

And so, one day it happened, perhaps 5.000 - 6.000 years ago, a huntsman felt an urge to taste that white substance he found inside the stomach of a young calf he had just taken down – and found it to be cheesy milk! Thus, it is safe to say cheese is probably one of the oldest and natural dairy products known to man. Many years later, farmers began to make water containers out of dried animal stomachs and calf stomachs were no exception. Much to the farmers surprise, they discovered when they poured fresh milk into the containers made from calves, the milk separated into they and curd. Little did they know that the calves’ stomachs contained and released a substance that caused milk to coagulate and turn to cheese. Today, we know this substance as rennet and still depend on it for making cheese. This animal rennet can only be derived from the stomach of young animals still drinking their mother’s milk, as production stops once the animals mature and gradually begin to eat grass. A similar story speaks of an Arab tradesman who set out to cross the dessert. To make sure he would suffer no thirst - nor hunger on the journey – in a container made from sheep’s stomach, he carried fresh goats milk.

Since the journey ahead of him was long and troubled, he hasted through the dessert and felt he had no time to eat the dates or drink the milk he had brought with him. He intended to try and make it through the dessert before dark and leave no time for stops but late that afternoon he felt so thirsty and hungry he had to make a halt after all. When he brought the little leather container out and held it to his lips, he was astonished to realize only a clear liquid poured from it – that was whey! Surprised and curious to know what had happened to his delicious milk inside, he quickly slashed the bag open and was amazed to see a peculiar white lump inside – and this was the first cheese ever discovered. Since the traveller was hungry - and perhaps a little curious too, he decided to taste some of that peculiar soft white gooey and found, not only was it delicious but very satisfying for his hunger. Little did he know there was a scientific explanation for the transformation that seemed like a God sent miracle. The sheep stomach that lined the inside of his bag had of cause contained rennet and miraculously turned all off that lovely milk into delicious cheese as he rode through the dessert. Cheese was traditionally made from cow, sheep, buffalo or goats milk but as of the 16th century, cows’ milk has been favoured above other milk types for cheese production - at least in Europe. In other parts of the world people still make cheese as per old tradition from sheep, goat, buffalo, camels, reindeers or other species. Our modern day dairy cows, all descend from great pre-historic oxen that were huge in comparison with a shoulder height at 2 meters. These large animals were not domesticated and lived in the wild, roaming through grass- and woodlands in northern Europe, Asia and North Africa. Around 8.000 years ago, people in southern Europe somehow managed to domesticate these giant ruminants and we can only assume how they did it. Maybe they caught the young calves and nursed them into captivity, or perhaps they lured these giants into domestication by putting feed out for them in times of scarcity? The first domesticated cattle appear in Europe app. 5000 years ago, and farmers have through times picked out the best individuals with the most desirable trait to continue the line of breed. Thus, there are many different types of cattle today, some yield little milk but are highly favored for their fine meats, while other breeds yield large quantities of milk and have little value in terms of meat.

To sum it up it all up, animals were domesticated in Europe around 3.000-2.500 B.C. and we know the milk was already then used to make cheese from – a few thousand years after that huntsman had found curd inside the calf’s stomach. However, the secrets to advanced cheese making were poorly understood in Europe up until 1000 A.C. Danish Vikings acquired these skills through their countless raids and fares to other countries which were far more advanced on cheese making. Furthermore, skills were brought to Denmark by monks that later came to try and tame the wild Vikings and convince them to be good Christians. Up until the mid-1800’s in Denmark, a farmer would commonly only own a few cows, just enough to cover the family’s need for dairy products. All the cheese and butter was made by the women in the households and solely intended for the family’s own consumption – nothing was produced for selling. In the latter half of the 19th century this tendency began to shift as science-based experiments to optimize milk production discovered how cows yielded more milk if they were fed a particular diet. This knowledge soon enabled farmers to produce more milk and make larger quantities of high quality butter available for sale and export. In 1882 the first Danish dairy cooperatives were established and they mainly produced butter for export. Although many small dairies also experimented with cheese production, sales remained low scale until after the 2nd world war. When the war ended, butter production declined while cheese production and export went up.

A man to greatly influence Danish cheese production was the Danish chemist Chr. D. A. Hansen. During his early years as a student in the 1870's, he realized how much the growing dairy industry and cheese production would benefit from a high quality standardized rennet product. From dried calves stomachs he developed a rennet product that became widely renowned in the world – and was the beginning of today’s company called Chr. Hansen – still a major player on the market for enzymes and cultures. Other Danish companies worth mentioning, is Danisco (today; Du Pont) and Novozymes. They too, have played an important role on the market as developers and suppliers of quality products for cheese production. |

Cheese categories

Cheese categoriesThere are two fundamental ways of separating whey from milk to make cheese, categorizing them into either - acid-set cheeses or rennet-set cheeses. Whey cheese is a third cheese category and as the name suggest, they are made from whey. Whey cheeses are greatly treasured for being nutrient dense and it contains lots of beneficial nutrients.

Acid-set cheesesare the easiest and quickest types of cheese to make and they can often be savoured newly made with no need for aging. These are always made from soured milk – not old milk, but milk intentionally left at room temperature for a particular length of time to ferment and thus acidify. To enhance this process, the milk can be preheated to 20-25°C, then cultured with buttermilk or soured milk and left at room temperature for a while. After 24 hours, the milk has become so acidic it naturally coagulates (curdles) when it is heated to 60°C. By then draining the whey off – either by letting it run off or by lightly straining it, a denser texture forms. Qvark, fresh cheese, buttermilk cheese and smoked cheese are a few examples of acid-set cheeses. There are variations of the acid-set cheeses where the milk is not acidified by fermentation but by adding an acidifier like lemon juice, vinegar, citric acid or tantaric acid. When milk is heated in combination with adding an acidifier, it coagulates just as well as if it had been acidified by fermentation. However, the milk tends to take flavour after the acidifier and depending on how much you add and how acidic it is, it will impact the texture and hardness of the cheese too. If the milk is either too acidic or heated too much, the texture can become like Halloumi - a semi-hard cheese that does not melt when pan-fried.

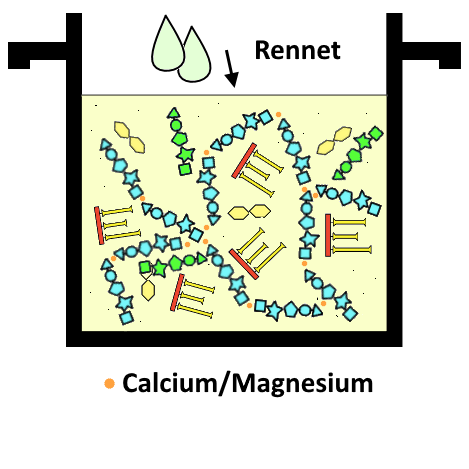

Rennet-set cheesesRennet coagulates milk in a different way and by the act of the enzymes contained in Rennet. Rennet is a protein with the ability to change the milk proteins into a new type of protein with different properties. These new proteins can form a tight structure that solidifies the milk – and that is what coagulation is. This protein structure traps and incapsules other milk substances like fats, sugars and also whey at first, but that is expelled after a short while when the structure tightens. Most of the solids like fats and sugar remain trapped within the protein structure. Just like with acid-set cheeses, acidified milk is important to the process when making rennet-set cheeses. Rennet-set cheeses too, are made from fermented milk but the acidification process is not quite the same. For the coagulation process to happen correctly, the acidifying process must have only just begun when rennet is added. This means the acidification process will be on going and continue even after the milk has coagulated and that too will help promote whey drainage. The reason why milk can ferment and acidify is its content of sugars (lactose). When lactic acid bacteria in the milk digest lactose, they produce lactic acid and other substances in the process. There is a great number of different species of lactic acid bacteria, each contributing with different types of flavoring to the cheese which is why the choice of lactic acid bacteria matter to the overall flavour. Even other enzymes and bacteria can contribute to the overall taste and texture, with different flavoring substances as a result of breaking down fats, proteins and sugars. Rennet-set cheeses vary a lot in taste and appearance, just think about the differences between Feta cheese, Brie, Camembert, Gorgonzola, Havarti and Danbo – just to name a few. Even though they are all basically made from the same set of ingredients, small differences in the preparation process, choice of cultures or enzymes, hugely impact how these cheeses fall out.

Whey cheesesis made from whey, the by-product you get when you make either acid-set cheeses or rennet-set cheeses. Nearly 20% of the milk proteins are not susceptible to coagulate by the methods we use when making acid- or rennet-set cheeses, thus these proteins remain suspended and drain off along with the whey. Whey protein is a highly cherished source of protein amongst sports people as it is easily digested and supplies building blocks for muscles and health. When whey is heated to temperatures above 85°C, the proteins fall out of solution and coagulate and this is how cheeses like Ricotta or brown cheese (mysost) is made. To increase the fat content and make creamier whey cheese, they can be made purely from milk or from a mixture of milk and whey. As described above, there are numerous ways to vary the cheese making process that will impact how a cheese falls out and when considering the many different options for combining methods, ingredients, enzymes and bacteria, it is roughly estimated that nearly 2000 different cheeses can be made. Surely, some of them would only differ slightly but that is what makes cheeses so compelling to many of us. |

Cheese types

Cheese typesThere are many different types of cheese since the smallest of variances in how the cheeses are made, affects how they turn out in the end. Right from the choice of milk – where it came from and how it was processed - to the choice of culture and the cheese making process itself – this makes all the difference and how very fortunate! Cheeses are like wine. It is the great variety and nuances in flavors that makes it so compelling to us to taste them and make us want to try more – and preferably with wine to make the experience even more pleasurable. However, fundamentally cheeses can be categorized into these 3 different types; dipped cheese, kneaded cheese and close texture cheese.

Dipped cheeseRefers to cheeses where the curd is scooped out of the whey, allowed to drip off and then filled into moulds. Light pressure may be added to seal the surface of the cheese or some are briefly lowered into hot water to prevent air, water and bacteria from entering the cheese as this will influence the maturation process. A dipped cheese appears with several irregular cheese holes – examples of such cheeses are Havarti and Esrom cheese. Kneaded cheeseRefers to a cheeses where the curds/cheese grains are kneaded after drainage to make them evenly sized. This process results in a nice smooth and even surface with regular cheese holes. Salt is often added while kneading the curd to enhance flavours and make the texture firmer. Adding salt also slows the activity of enzymes, hence maturation slows and makes a milder cheese in the end. Once the cheese grains have been carefully kneaded, they are filled into cheese moulds and pressed several times before chilled, salted and left to mature. There are only two Danish examples of kneaded cheeses – Maribo and Fynbo. In terms of taste, they are like Gouda or Cheddar cheese. Close texture cheeseRefers to cheeses where the curds are pressed while still in the whey. This prevents the formation of air pockets and air from entering which gives these types of cheese a nice smooth appearance with few or no cheese holes. After pressing the cheese, it is cut into smaller pieces and matured. A few irregular cheese holes might form during the maturation phase as lactic acid bacteria produce CO2 while digesting the remaining sugars. Samso and Danbo are examples of Danish close textured cheeses. In Denmark, the most popular cheese types are the semi-hard cheeses like Danbo, Esrom, Havarti, Maribo and Samso but even Danablu, a semi-soft blue mold cheese – and lastly rygeost which is a soft fresh cheese. Worldwide, the most famous types of hard cheeses are; Cheddar, Crottin de Chavignol, Emmentaler, Fontina, Gruyere, Manchego and Parmesan. For semi-hard cheeses, it is Provolone, Gouda and Port Salut and for semi-soft cheeses, it is Feta cheese and Mozzarella. There are also a few of well-known blue mold cheeses, these are Gorgonzola, Roquefort and Stilton – and the white mold cheeses, Brie and Camembert. For washed rind cheeses, it is Munster and cottage cheese, qvark and cream cheese are commonly known soft fresh cheeses. |

Cheese list

Cheese listBelow is a description of different types of cheeses listed in alphabetic order. This is not a complete list since the world of cheese is quite a large one. Besides, many cheeses with different names covers the same type of cheese made by the same methods - the only difference is where it is made. Alpes cheese (Green Alpes cheese)Alpes cheese, as it is known in Denmark, is a cheese spread with granulated herbs, primarily Alpine clover but it even contains species like Melitotus coeruleus, Melilot sap, Trigonella caerulea, Fenugreek too. This cheese was originally inspired by a hard cheese seasoned with clovers, called Schabziger Kräuterkäse. AppetitostAppetitost is a semi-soft Danish cheese based on buttermilk and made like a fresh cheese but with a small amount of rennet. The curd is heated to give it a firmer structure and during the course of a few days, it is repeatedly pressed, crumbled and heated to promote whey drainage. The result is a tough yellowish curd to finally be heated with a small amount of milk, kneaded with salt until smooth and then left to mature for a few days. No further maturation is needed, it can be savored as it is. BrieBrie is a soft white mold cheese with a white moldy rind - a famous French cheese traditionally made from cow’s milk. The French name is fromage de la Brie - meaning “the cheese of Brie”, a rural district east of Paris with a main town named Meaux. Therefore, the original Brie cheese is called Brie de Meaux. The original Brie is made from unpasteurized cows’ milk and by many considered to the best and only true Brie. The history of Brie cheese is long but it first acquired world fame in 1814 when European statesmen held a congress in Vienna to discuss the political future after Napoleons defeat. Great luscious banquets and entertainment accompanied the congress and fort sprung the idea to point out the world’s best cheese. More than 60 cheeses competed for the title but Brie cheese took first prize and was honored with the name “king of all cheese” - a title it still carries. The Brie cheese is thought to be the mother of all white mold cheeses. They mature from the outside and inwards contrary to blue mold cheeses that matures from the inside and outwards. The mold cultures applied to Brie is Penicillium camemberti/Penicillium candidum. CamembertCamembert is a soft white mold cheese with a slightly aired structure and a white moldy rind. It origins from France and is made from cows’ milk. Camembert cheeses dates as far back as the 18th century where it was sold on the local market in Vimoutiers, Normandie. The cheese is named after the town of Camembert in Normandie. The recipe for camembert was developed by a woman named Marie Harel in 1790 and said to be greatly inspired by a French priest who took refuge in the house where Marie Harel worked during the French revolution. Together they are believed to have developed the recipe for Camembert, greatly inspired by brie cheese. Marie Harel later passed the recipe on to her daughter who settled in the town of Camembert and began to produce and sell it there. Camembert cheese became such a success, a statue of Marie Harel was made in her honor – unfortunately, this statue was destroyed during the 2nd world war. Camembert cheese acquired its national fame and acknowledgment when Emperor Napoleon first tasted the cheese after opening a new railway line in Normandie. He was so impressed, he ordered for a delivery to Paris and since French high society followed whatever the emperor did, the fame of Camembert cheese was a given. Today, the original Camembert is sold under the name of “Camembert de Normandie”. A Camembert contains the mold cultures Penicillium camemberti / Penicillium candidum, and these are important to the maturation of the cheese. Castello (ble or white)Castello is a range of Danish mold and cream cheeses, developed in the late 1960’s. Chester, Leicester, GloucesterRich English rennet-set cheeses similar to Cheddar cheese. CheddarCheddar cheese is made almost anywhere in the world today but was originally made in England. It is a kneaded hard-cheese with some elasticity, light-brown dry rind and is made from cow’s milk. Cheese has been an important food in England for over a thousand years and it is almost certain when someone English speaks of cheese, they almost always mean cheddar cheese. Cheddar cheese has been known since the 16th century and come from area near Mendip Hills, close to the town of Cheddar. There is no doubt the history of English cheeses dates even further back – perhaps as far as the Romans who may have introduced the skills to make hard-cheeses to England. Shape, size and weight of a cheddar depends on where it is made. Unlike most other European cheeses, “cheddar cheese” is not protected name and may be used and misused by anyone. Today, Cheddar cheese made in the traditional way, is only produced in a few localities across the world. Crottin de ChavignolCrottin de Chavignol is a semi-hard, matured cheese with a natural rind. It is made from goats’ milk and originates from the district of Loire in France – by some, this is also called the smallest cheese in the world. It was developed in the 16th century where farmers in Sancerre herded goats and made their living on selling goats cheese. They developed the Crottin de Chavignol. The goat cheeses from Sancerre were named Crottin de Chavignol in 1829 and the word Crottin means little terracotta oil lamp which the cheeses take shape after – however, it also means horse-droppings which have sometimes lead to some funny conversations and remarks about this cheese. DanabluDanablu is a Danish semi-soft, creamy, blue mold cheese with marbled rind - made from cows’ milk. Danablu was developed before the 1st world war where Danish dairy men began experimenting with different mold cultures for blue mold cheeses. Danablu was developed by a man named Marius Boel in 1927 and he was the first ever to make a blue mold cheese from homogenized milk which is the secret behind Danablu’s unique texture and aromatics. Compared to Roquefort cheese, Danablu came out richer, whiter and offered a newness of taste, unlike anything known at that time. Marius Boel used a blue mold culture he had grown on a piece of rye bread to culture and produce the first Danablu. Today, this particular mold culture is made in proper facilities and only a limited number of dairy facilities has the right to make Danablu. Danablu is a high fat cheese with a fat content around 50+ and it is always cylinder shaped. The even richer Danablu 60+ is always squared. A few light versions exist too (30+) but these are not considered original Danablu due the low fat content. DanboDanbo is a Danish close textured, rennet-set cheese made from cows’ milk. The texture is semi-hard with regular cheese holes and the rind is dry. Danbo was developed in 1897 by Rasmus Nielsen at Kirkeby cooperative dairy. At that time, he had a hard time convincing the other members of the cooperative of the sense in producing such a high-fat cheese and it was not until he got the opportunity to lease the entire dairy facility, he was able to set up a production by him-self. A visit to the East German steppes near the Polish/Russian border had inspired him to make this cheese and even though he had also been to Holland to learn how to make Gouda and Ejdammer, it was this cheese inspired by a German steppes cheese that was most successful. It was given the name Danbo. Today Danbo is the most commonly produced cheese in Denmark and comes in many different variations with different lengths of maturation. Danbo is also made with cumin, better known as ”Christian IX” cheese. EsromEsrom is a Danish semi-hard and rennet-set cheese, it is a dipped cheese with irregular cheese holes and a thin greasy rind. Esrom cheese is thought to have been developed by Cistercian monks who lived at Esrom monastery north of Copenhagen although it could have been inspired by local farm house cheeses. Esrom cheese was produced at the monastery which partly exist today, now houses a museum. Since the monks took great pleasure and interest in developing cheese, it is however most likely to think Esrom cheese was solely their invention. After a time of political reformation in Denmark, Esrom monastery fell into hands of the King and the buildings were partly torn down while the cheese was more or less forgotten. Esrom cheese was rediscovered in 1937 when it was first reproduced by the national experimental dairy institute in Hillerod. It is made by a unique Danish method where culture is applied to the surface to promote faster maturation from the outside and inwards as well as the inside outwards. Only four approved dairy facilities produce Esrom cheese today. HavartiHavarti is a Danish semi-hard rennet-set cheese, it is a dipped cheese and made from cows’ milk. The texture is aired and dotted with plenty of little cheese holes and the rind is thin. One of the greatest cheese makers in Denmark was Hanne Nielsen (born 1829) She developed the Tilsiter cheese, later known as Havarti cheese. The cheese is named after her farm “Havarti farm” near Holte, a town north of Copenhagen. MariboMaribo cheese is a semi-hard, rennet-set, cheese with a dry yellowish rind. It is made from cows’ milk and is the only kneaded cheese made in Denmark. The kneading process contributes to a smooth texture dotted with quite a few small irregular cheese holes. The cheese is named after the Danish town Maribo. The production of Maribo cheese is only very small scale today, and it often appear in a rectangular shape. It is very similar to Dutch gouda cheese and went under the name “Danish kneaded Gouda” up until 1952. Smoked cheese and KnapostSmoked cheese is a unique Danish specialty. It is a soft fresh cheese with no rind, like a fresh cheese, smoked but not matured. Smoked cheese is the only cheese with true Danish origin, not inspired by cheeses made anywhere else on the world. Fresh cheeses are thought upon as the traditional cheese and rightfully so, since they are very easy to make. To smoke a fresh cheese is an old Danish tradition that appeared in the 17th century as a local specialty on the island of Fyn. Smoked cheeses may have been made of much earlier, perhaps as far back as the Viking age where fresh cheeses were already known. However, it was local farmers on Fyn that made it in to a famous national specialty and this is why, it is often spoken of as smoked cheese of Fyn (Fynsk rygeost). Almost all smoked cheeses are produced in small dairy facilities on Fyn, today. Smoked cheese is made by moulding the curd in into small sized flat cheeses that are placed on a grill and smoked over straw and dried nettles. They are smoked for a few minutes on each side until they become slightly golden with grill marks – some are sprinkled with cumin. Smoked cheese is also known as Rogeost. Knapost is made from the same basis as smoked cheese, only it is not smoked but cumin is always added. Klosterost is also a similar Danish specialty based on a fresh cheese. The texture is hard, flavors are strong but it is never smoked, nor is cumin added. ElboElbo is a rennet-set cheese. EmmentalerEmmentaler is a Swiss cheese named after the Emme Valley in Kanton Bern where it has been produced for many centuries. Emmentaler has a yellow-brownish dry rind and is made from cows’ milk. For hundreds of years Emmentaler cheese was produced by the Senne-shepherds, herding cattle far up in the Alpes every summer. Not only did the shepherds own most of the cattle themselves but also had they access to some of the best highland grazing. They used their small shelters and cabins to make cheeses from and had them carried down into the valleys by mules and sold on marketplaces. Emmentaler cheeses were smaller back then and did not weigh more than 4-10 kg. In the 15th century the shepherds acquired the skills to produce larger Emmentaler and how to keep them fresh for longer. This satisfied a growing demand for Emmentaler cheese but it may also have been brought about a French import tax inflicted per piece, regardless of size. The original Emmentaler cheese is still made in Switzerland and this is printed into the rind. FetaFeta cheese is a semi-soft rennet-set cheese with high salt content and no rind. It was traditionally made purely from sheep’ milk but today it is even made from cow or goats milk. The true origin of Feta cheese is unknown but it is thought to be somewhere in the region of Croatia and Iran. Feta cheese has though times been produced in many places and most likely in many variations, however for several decades now, Greece have claimed it to be a Greek specialty with Greece as its true origin. The countryside in Greece is rough and not very fertile, mainly suitable for low scale farming. Thus, herding goats and sheep was for centuries one of the most well paid jobs because these animals do quite well in dry climate where grassland is scarce and sheep or goats milk has been the sure source of protein in the Greek diet for generations. In 1996 Greece was granted the sole right to use the term Feta Cheese. Authorities in Denmark, Germany and France protested and took it to the EU Court, pointing out that feta cheese is a cheese type rather than a Greek specialty. They also pointed out that the true origin of Feta cheese is unknown, and so in 1999 the EU court annulled Greece’s exclusive right to use the term Feta cheese. Cream cheeseCream cheese is made from fermented cream and is usually not rennet-set. To make cream cheese, the curd is heated several times and seasonings is oftentimes added afterwards. For this reason, there is a vast variety of different cream cheeses, some are plain, some seasoned with herbs, some are flavored with spirits, nuts or fruit. Fresh cheese (Skorost)This is a non-matured, fresh cheese made from whole milk. Qvark is a similar sort of fresh cheese but this is made from skimmed milk. Fresh cheese is an acidic tasting cheese with high fat and high protein content. FontinaA Fontina is a semi-hard Italian cheese, made from unpasteurized cows’ milk. The texture has some elasticity to it, the development of cheese holes is scarce, the rind is hard but thin and has an orange to slightly brownish color. Fontina is the oldest known Italian cheese, named after the Fontin mountain near Aosta in the Piedmont-province in northern Italy. An area that boast some of the highest mountains in Europe and provide plenty of lush green highland pasture for grazing. These pastures have been important to cheese production since the 11th century. Back then local cheeses were simply referred to as “caseus” meaning; ”made from cow’s milk”. Fontina cheese is said to be scented and flavored by these rich blooming highland pastures. Fontina cheeses are matured from 2-6 months, usually 3 months and every maker of the Fontina cheese has his own preferred place to do so – this could be in caves, tunnels, old mines etc. GloucesterThis is a rennet-set Cheese – see Chester cheese. GorgonzolaGorgonzola is a semi-soft elastic blue mold cheese with a moist reddish rind. This cheese is always made from cows’ milk and originate from Italy. Gorgonzola cheese was first produced more than a thousand years ago, in the little North Italian town Gorgonzola. Traditionally it went under the name Stracchino di Gorgonzola. Stracco means tired in Italian - and with good reason was this name given to the cheese. Gorgonzola cheese was traditionally based on milk from cows that had just been herded from the steep highlands into the meadows of the Po valley. The journey made the cows tired and gave their milk a rare texture that was the basis of a Gorgonzola cheese. A story also speaks of a young man, who once neglected his duties as a cheese maker to spend some time with his girlfriend. When he returned in the morning, he accidently mixed the morning milk with the evening milk – and this is supposedly how the first Gorgonzola was made. Traditionally, Gorgonzola cheeses were matured inside caves in the Valassina valley. Up until the 19th century Gorgonzola cheese was merely a local specialty but ever since has it been famously known in the rest of the world. Today only approved dairy facilities in Italy produce the original Gorgonzola per strictly regulated standards. Gorgonzola cheese made elsewhere in the world is not considered original and entitled to the Gorgonzola name. GoudaGouda cheese is a semi-hard rennet-set cheese with a hard dry rind, often coated with paraffin and always made from cow’s milk. Gouda cheese is a Dutch cheese thought to first have been produced in the town of Stolwijk and later given the name Gouda after a town in southern Holland. Traditionally, Gouda was known in the world as the Dutch farmhouse cheese since this is where it was first produced, on the dairy farms by women that was the precursors to actual dairy facilities. Today, Gouda cheese production makes up more than 60% of the total cheese production in Holland and is mainly produced on large dairy facilities. Only a small number of dairy farms make Gouda cheese per old times standards on the farms. Unlike most other countries, Holland has primarily based its cheese production on two types of cheeses – Gouda and Edam. Both have had a significant impact on Dutch economy and almost any other type of cheese seems to derive from these two. Edam cheese is softer than Gouda and has a lower fat content. It is shaped like a ball and usually has a red wax rind. Holland have no set standards or regulations for the production of these two cheeses, thus a vast number of non-Dutch reproductions are made across the world. Sometimes Gouda is seen flavored with garlic, nettles or herbs or even smoked. The Danish Cheese, Maribo is an example of a cheese that was inspired by Gouda cheese and is very similar to it, only it has fewer cheese holes. Previously Maribo cheese went under the name “Danish kneaded Gouda” or “Dutchmen’s cheese”. GruyereGruyere is a semi-firm-elastic, rennet-set cheese with a golden-brown rind and only few cheese holes. It is made from cow’s milk and originate from an area of France or Switzerland, although it is named after the district of Gruyere in Switzerland. The history of the Gruyere cheese date as far back as the 12. century to when the duke of Gruyere founded Rougement monastery in 1115. He then claimed a church tax from people of the entire region and cheese was part of these payments – today known as Gruyere cheese. Gruyere cheese belongs to the same family of cheeses as Emmentaler, although gruyere has fewer cheese holes and the texture is harder and crumbles more but the shape, how it is made and the maturation process, is very much the same. A Gruyere is also known as Emmentaler’s little brother. Gruyere cheese requires at least 1 year maturation to fully develop its unique flavors and it is only produces in the western part of Gruyere which is also the French speaking part of Switzerland. Cottage cheeseCottage cheese is a grainy cheese, rennet-set and the curd is heated to promote faster whey drainage. Cottage cheese can be mixed with cream and herbs. KetalotyriKefalotyri cheese originate from Cypress or Greece where it was traditionally made from goats or sheep milk but today some are made from cow’s milk too. A Kefalotyri is an aged hard cheese with high salt content and significantly flavored by the lipase enzymes – a flavor that intensifies the longer it matures. Kefalotyri is often used for cooking as it is ideal for shredding, especially the 40+ is whereas the 45+ is lot better for making Saganaki. This is thick cut slices of cheese, pan-fried and served with a salad. This makes a delicious starter for any meal. Klosterost (Monestary Cheese)This is an old Danish specialty made like a rennet-set fresh cheese. Rennet adds more firmness to the texture and intensify the flavors. QvarkQvark is a fresh cheese made from skimmed milk, eventuelly rennet-set. The taste is acidic, it is low fat and have a high protein content. To be savored as it is or scented with vanilla. ManchegoA Manchego is a Spanish rennet-set cheese made from sheep milk. It has a semi-hard to hard texture with a dry and yellow / black rind, sometimes coated with paraffin. Sheep milk cheese is very common in Spain and have a long tradition because of the dry climate being favorable for sheep and provide low quality grazing for cattle. Manchego cheese originate from La Mancha, the highland region in Spain made famous in Cervantes’ novel, “Don Quixote”. Shepherds here, have made Manchego cheese as far back as the roman times but the landscape has changed since then. Where only sheep used to graze is now vineyards as a result of modern day irrigation. A Manchego cheese is usually matured for about 3 weeks but flavors will improve by up to 10 months’ maturation. A milder Manchego, Curado, matures for 13 weeks, while Manchegos that mature more than 3 months is known as “Viejo” and for those that matures for over a year, it is “Anejo”. In some parts of Spain, Manchegos are treated with olive oil, a speciality called “Aceite”. MolboA Danish close texture Cheese – like Danbo. MoroliqueThis cheese has a distinct acidic flavor and a high salt content like feta cheese – and therefore it tastes a bit like it too. It is rarely aged for longer than 3 weeks but flavors certainly improve by leaving it for as much as up to 10 months. Morolique is a hard cheese, pressed in chunks of 50 kg for up to 48 hours. MozzarellaMozzarella cheese is a semi-soft elastic fresh cheese with no rind and was originally only made from buffalo milk. Mozzarella di Bufala has a long history that can be traced back to Salerno in southern Italy where it was first made. Today, Mozzarella is widely known accross the world famous for its use as pizza topping. Mozzarella cheese today can be made from either buffalo or cows’ milk. A buffalo mozzarella has more intense flavors and is the only Mozzarella rightfully entitled to the name Mozzarella di Bufala. The name means “buffalo eye” and refers to the round shape. Italian Mozzarella made from cows’ milk is called Fior di Latte and smoked Mozzarella is called affumicata. There are even Mozzarellas made from a mix of buffalo and cow’s milk. When you buy a mozzarella, it is almost always bagged soaked in its own whey. Mozzarella cheeses made in Denmark are only made from cows’ milk and do therefore not have the same intense aromatic flavors like Buffalo Mozzarella. However, it is only the milk type and shape that differs, they are produced in almost the same way although the Italian buffalo mozzarella is a fresh soft cheese perfect for salads whereas a Danish mozzarella is firmer and better aimed at cooking. MunsterMunster is a semi-soft French cheese with an orange-red rind and it has few or no cheese holes at all. It is made from cow’s milk and the mold culture Pencillium roqueforti is applied. Munster is probably the most well-known washed rind cheese. It is produced in Munster valley in Vogeserne close to the French-German border in Alsace-Lorraine. It is believed to be Irish monks settling in Vogeserne in the early middle ages that first developed this cheese, as the name most likely derives from the French word; monastere meaning monastery. When a Munster cheese is made ready for maturation, it is air-dried before it is stored in cellars alongside aged Munster cheeses. By lying next to aged Munster cheeses, a young unripe Munster get innoculated with the red rind culture that already flourish on the aged cheeses. This require a minimum of 21 days maturation and the rind must frequently be washed with saltwater to promote development of the characteristic red rind culture. Munster Gerome is another type of Munster cheese. It is also from Lorraine and is like a Munster, only smaller - some can weight as little as 120 g. Munster au Cumin is a Munster with Cumin and is quite a popular variation. French Munster cheeses are produced close to the German border, thus German productions of Munster cheeses exits too. MycellaMycella is a Danish type of Gorgonzola. It is a creamy blue-mold cheese with mild and aromatic flavors. Mycella is made from cow’s milk and has its name after the Latin word mycelium. Mysost (Brown Cheese)Brown cheese is traditionally made from whey and sometimes extra added cream. By heating whey at high temperatures, a brownish firm curd forms and that is the basis of brown cheese. ParmesanParmesan is a hard cheese from Italy made from cow’s milk. It has no cheese holes and the rind is either yellow or dark. The original Parmesan cheese is called Parmigiano-Reggiano, developed in the 10 or 11th century in Bibbiano in Italy. The name Parmigiano-Reggiano reflect its origin, referring to the two Italian provinces “Parma and Reggio Emilia”. A strict set of production standards for Parmesan was outlined in 1955, regulating as far as to what feed the cows should be fed, allowing for fresh grass, hay or alfalfa hay. Italian Parmesan cheese is only produced from April to mid-November and require at least 24 months’ maturation for the flavors and texture to develop correctly. In Denmark, a Danish variation of parmesan is produced by Ranum Dairy and sold under the name Ranumi Regatto. Grana Padano is another Italian variation of parmesan and the difference is shuttle. The production methods for the two Italian cheese are almost the same, except Grana Pandano is made in larger cheese vats and the morning milk is never mixed with the evening milk, like it is when making original Italian parmesan. Furthermore, Grana Padano matures for only 12 months and is made from pasteurized milk. Port SalutPort Salut is a French semi-soft cheese made from cow’s milk. It has a smooth texture and the bright orange colored rind is eatable even though it not natural. Port Salut can be traced back to the monastery “Notre Dame de Port-du-Salut” in Entrammes, Normandy. The recipe for Port Salut is believed to have been developed by Trappist monks, returning to Notre Dame having lived in exile under Napoleons reign. They returned to the monastery with cattle and began a production of a magnificent cheese solely meant for their own consumption at first. When they later gained access to more milk supplies from local farmers, they were able to increase production and make it a local specialty for more people to enjoy. ProvoloneProvolone is a semi-hard rennet-set cheese from Italy, made from cow’s milk. It is a kneaded cheese with few cheese holes, a thin rind and often coated with paraffin. Provolone cheese has a long history and was already a favorite amongst the romans who preferred it aged and smoked. No one really knows where it was first made just that it was one of the first cheeses known to the romans. Provolone Valpadana is the official name but there are many local names for it - often referring to the shape and size that tend to vary a great deal. Provolone cheese is moulded under hot water and can either pear shaped, flat, rectangular or shaped like a cylinder – it solely depends on the preferences of he who makes it. For example, is the the Giganti-cheese up to 3 meters long but usually they are a lot smaller and often cylinder shaped. Provolone-cheeses commonly hang side by side from strings in the ceiling while they mature. A mild Provolone is called a Dolce - an older Provolone is a Picante. There are many different Provolones and some of the Italian ones are: Pancettoni, Giganti, Mandarine, Provole, Ragusani, Salamini, Silani, Topolini and Bocini. Some Provolones are smoked. RicottaRicotta cheese is made from heated whey, sometimes by applying an acidifier like vinegar or lemon juice – and sometimes extra cream is added to make it creamier. When whey is heated, the remains of milk proteins in the whey coagulates and form a new type of curd. Ricotta cheese is a fairly low-fat cheese. RoquefortRoquefort is a French semi-soft blue mold cheese made from unpasteurized sheep milk. It has no rind but it will often develop a type of yellow greasy coating. The cheese is named after the small town Roquefort Aveyron, in South-Eastern France, an area that provides optimal conditions for aging Roquefort. It is not so much the sheep milk that makes a Roquefort special, it is the aging process inside grottoes in the Combalu mountain. These grottoes provide unique and perfect conditions for maturing blue mold cheeses, so much so that many have tried to duplicate and establish these conditions elsewhere in the world. The best grottoes are those with the best “fleurines” which is a term for the large shallow cracks in the grotto walls. Some of them can be up to 100 meters high, supplying the grottoes with a constant airflow around 8-9°C with a 95% humidity. This seems to be the perfect natural air conditioning system for aging blue mold cheese. The roots of the Roquefort cheese can be traced as far back as 79 A.C. but it might be even older than that. Roquefort cheese is only made from February to august which is the period where sheep lactate and the milk is supplied from all regions of France. In the old days, it was only produced by local farmers but today Roquefort is mainly produced in larger dairy facilities. The original Roquefort cheese is made from sheep milk and aged in the Combalou grottoes, near Roquefort – if not, they are not rightfully entitled to the name Roquefort. This cheese is with good reason spoken of as the mother of all blue mold cheeses. Red rind cheese / Washed rind cheeseRed rind cheeses have their name because of the culture that smears the outside of them, once applied. This is what gives them their red-orange appearance and helps ripen them from the outside and inwards. It can be applied to firm as well as soft cheeses. The rind is frequently washed in brine throughout the ageing process to make it susceptible to the development of the culture. Thus, these cheeses are commonly referred to as washed rind cheeses. The texture of a red rind cheese is often smooth and creamy and that tends to intensify as it matures. Melted cheeseMelted cheese is what the name indicates – a type of cheese made by melting cheese. It was developed to add prolonged shelved life to cheeses and is made by mixing bits of firm cheese with melting salts (phosphates), citric acid and seasonings and then cooked at high temperatures. When it cools off - ham, shrimps, herbs or other seasonings are often added to flavor it. Cheese spread (Labne/Labneh)Cheese spread is made by draining yogurt or cream fraiche, Fromage frais or another fermented milk product, then adding salt or herbs. Sometimes it can be seen stored in olive oil. http://cookalmostanything.blogspot.com/2006/09/making-labne.html SamsoSamso Cheese is a Danish rennet-set cheese, close textured with few cheese holes and appears with a dry yellow rind. Samso cheese has been produced for generations on the Danish Island Samso. The production began in the 19th century where Danish dairies began to take an interest in producing foreign cheeses for the home marked. Samso cheese was developed when dairy man Constantin Bruun invited a group of swiss cheese experts to Denmark to help him set up a production of Emmentaler. The initial production was a success but the recipe has undergone further development since to become what it is today. This Danish-Swiss invention was officially named Samso in 1952. StiltonStilton is an English semi-soft blue mold cheese made from cow’s milk and appears with a natural brownish rind. For centuries, it has been disputed who developed the first stilton but one story speaks of a Mrs. Paulet, housekeeper at Quenby Hall. Her brother in law ran the renowned The Bell Inn conveniently situated by the old roman cause way in Stilton - “The Great North Road”. It is said that Mrs. Paulet supplied her brother in law with cheese for the visitors at inn and this explains why is soon became delicacy across the country. ThyboThybo cheese is made either as a close textured or kneaded cheese, not unlike Gouda cheese and comes in variations with or without cumin. Thybo was the most popular Danish cheese during the middle ages and the first Danish cheese to be named a historical name. In the beginning of the 20th century it was changed to Taffelost but after a while it went back to its original name in 1952 – this time spelled; Tybo. The name roots back to the 15-16th century, referring to a time where cheese was part of tax payments from farmers to the local priest. Thybo-cheese is mentioned as early as the 16th and was even described as the best cheese in the North by Popes household people in Rome. Sources: |

Cheese production

Cheese MakingTo produce homemade cheese, you need some essential equipment, high quality milk along with specific enzymes and cultures. |

A cheese is born

A cheese is born

|

||||||||||||||||||||||||

The work process

The Cheese Making ProcessThe amount of action hours it takes to make cheese only varies little between the different cheese types. To make 2-3 kg of Feta cheese only takes about 2-3 hours spread out over the course of a couple of days. If you work during the week, it is ideal to begin the process on a Saturday morning and finish the last bits on a Monday morning. A large percentage of the work goes in to cleaning before and after. For this reason, we prefer to use dishwasher safe tools to reduce the work load of cleaning. All we need to do before beginning the process is to sterilize the equipment with boiling water. To make milk into cheese – these are the basic steps you follow:

The first steps are those that requires most attention for and for the first couple of hours. To make Feta cheese, for example, you spend the first couple of hours mixing ingredients, stirring, checking the temperature and empty the cheese trays from whey. When that is completed, the process become less and less work intensive and you only need to empty the cheese tray from time to time as whey drainage slows and progress until next morning. The next step is salting, and that takes about 2-3 hours on day two. Hereafter, the cheese is ready to be stored and matured for a few days. Feta cheese can usually be enjoyed freshly made but just know it gets even better if it is matured in the fridge for a week. The longer it matures the more flavours intensify and develops. Maturing it for 3 month usually makes it quite strong. For cheeses types like Brie and Camembert the cheese making process is quite similar. What makes them differ in appearance is more a result of adding different cultures and enzymes, and different maturation processes than the actual work process. Feta cheese is matured in brine/oil while Brie and Camembert are wrapped in cheese paper. Making semi-hard to hard cheeses are a little bit different because whey drainage requires more time and effort in comparison because these types of cheeses also require pressing. However, other than that, the cheese making process is not very different. They need longer maturation as flavors only begin to develop after 3–4 weeks of maturation. The first few of times you try make homemade cheese it probably seem as if it takes much longer but you will quickly learn to master the process and make use of the “off time” in-between. Know the beginning of the cheese making process always requires your full attention while sterilizing equipment etc. but after a while you only need to do something for a few minutes now and then - increasing from every 20 minutes up to days. It is important you are accurate and stick with the timing in the recipes, especially in the beginning when you are new to cheese making. It is a good idea to always set a timer so you know precisely when to act. Make sure not to begin the cheese making process before you are ready and have sufficient of time to follow through with the recipe without interruptions. Try to plan ahead before you begin and leave enough time to turn the cheese trays and salt the cheese as given in the recipe. It is crucial not to cut the time short or extend it. However, when you are more experienced, all the timings given in the recipes can be shorten or extended to your preference, as can the temperature be adjusted or cultures be reduced or increased. Just be aware each little adjustment you make will influence cheese acidity, texture, salinity etc. which is why we recommend you do not experiment too much before you have some experience in making cheese. When you are ready to experiment – only make one small adjustments at the time and see how that falls out. |

Requirements

PreparationsTo succeed in cheese making it important to play by the rules. If you do not play by the rules and deviate from the recipes, chances are that parts of the process change too much and may negatively affect how the cheese turns out. Having said that, it is also important to say that making small amendments to the recipes can be used to deliberately improve acidity, texture, salt content etc. to your own preference. This can be done by slightly changing either, temperature, timing or how much culture you add. Play with it once you have gained some experience as cheese-maker and have a feel for how the different phases work. Make sure only to make one little adjustment at the time to see how it impacts the cheese. CleaningHygiene is alpha-omega when making cheeses for the different phases go the way they are supposed to throughout the entire cheese-making process. If you are not careful about keeping everything clean and sterilizing equipment prior to beginning the process you may risk contamination with unwanted bacteria somewhere along the line and they will flourish during the maturation phase. This could negatively impact the flavor and for how long is stays stable for. Make sure you use only clean and sterilized equipment to make cheeses – the best thing is to have some you only use for this purpose. Make sure you have a clean dish brush at hand too and do not use your everyday dish brush to clean the equipment. It is advisable to also sterilize the cleaning tools with boiling water before you use them. The best thing is to use equipment made from food safe plastic or stainless steel. Avoid wooden kitchen tools or any other tools that can be difficult to clean and sterilize properly. IngredientsThe quality of all the ingredients must be high not to impact the quality of the cheese. Not only does it make a big difference if the milk come from cows, sheep or goats – it even matters what breed it comes from because of the fat content. How the milked animals have been fed and kept also impacts the quality of the milk which means even seasonal variations might influence how flavors and texture turn out in the cheese. Apart from milk quality, it also matters how the milk been handled and processed. This too may affect how flavor and texture develop.

EquipmentYou can use your ordinary kitchen tools to make cheese at home. It is not necessary to buy Hjemmeriets cheese kits but they do help you through the process. Especially cheese trays, cheese mats and moulds are very nice to have at hand and will ease the process while ensuring good hygiene. They are also very convenient if you want to make mould cheeses as they can help you create optimal humid conditions for the first maturation phase. This is of outmost importance to the correct development of mould cultures. AccuracyFollow our recipes accurately to get a successful result. Once you become more experienced and get a feel for how each little step affects the outcome, you can slowly begin to make small adjustments – one little step at the time. When you want to adjust fat content, temperature, timing, starter culture, enzymes or salt – we recommend you only make one adjustment at the time to see how it falls out. As with anything, sometimes we aim for the perfect result and get it – other times we do not. If something should fail in the process, just remind yourself it was an important lesson to improve future results. Trial and error, is what gives you all the skills you need to become a true master of anything. Maturing and storageFor cheeses that requires maturation, it is of outmost importance to provide the optimal conditions during this phase for it to develop and mature correctly. Make sure to mature your cheeses in a cool place with high humidity (or fridge) where germs from the surroundings will not contaminate the cheese. If the cheese needs to be turned from time to time during the maturation phase, make sure to wear clean food safe gloves or clean your hand thoroughly before touching the cheese. When maturing mould cheeses in the second phase, wrap them in cheese paper to protect them from bacteria and seal in moisture - this will help them mature. |

Tools

EquipmentTo make homemade cheese you need some equipment and you probably already have some of it in your kitchen, plus you need some extra tools from a cheese making kit. Standard kitchen tools

Cheese making kitTo make cheese you may also need a cheese kit with a few special tools, enzymes and cultures. Hjemmeriet have different cheese making kits depending of which type of cheese you want to make. With our standard cheese making kit you can make many standard cheeses. This cheese making kit contains: 2 cheese trays, 2 cheese mats, 4 moulds, a thermometer, droppers, cheese cloth, micro spatula, rennet, starter cultures and a booklet with some of our recipes. Go to our web shop to view the full range of our cheese making kits. |

Milk

MilkIn shops, markets or restaurants we get tempted by the mere sight or scent of a selection of delicious cheeses. Some are smooth – some are wrinkled. Some are bright yellow – others are pale white. Their shape, appearance, the taste of them and their texture is anything from unique to outstanding. Despite these differences, they are all made from the same thing – milk. |

What is milk?

What is milk?

Milk is by nature intended to nurture mammals at the early stages of their lives. It is secreted from milk glands containing the nourishment needed to support the growth and maintenance of a new born mammal. Milk or cheese flavor, highly depends on what type mammal it comes from – whether it is from cows, buffaloes, sheep or goats. Milk from cows generally has a sweet and delicate taste but that can even vary between breeds. There are more than 50 different breeds of milk cows and the taste of their milk differs. Thus, to serve as an example, milk from Jersey cows is more mild and mellow compared to milk from Holstein cows. Milk – Nutritional values

Links (texts in danish): http://www.maelkeudvalget.dk/Indvejning/Fedtprocent/Fedtprocent.htm http://www.maelkeudvalget.dk/Indvejning/Proteinprocent/Proteinprocent.htm http://www.maelkeudvalget.dk/Indvejning/IndvejningIKvorteaaret/Indvejning.htm https://www.researchgate.net/publication/272484270_Maelk_og_saesonvariation.... |

|||||||||||||||||||||||||||

Pasteurization

Pasteurization of milk

The different phases of the milking process always pose a risk of unwanted bacteria entering the milk, therefore milk directed for sales is always pasteurized (heat processed) to prevent contamination from unwanted bacteria and potential health hazards for consumers. Since lots of different substances in milk can be subject to damage when heated, pasteurization is performed as gently as possible. Milk is pasteurized by heating it to somewhere between 63 and 80 degrees and then chilled again. Pasteurization will denature (degrade) the whey proteins (albumin, globulin) in the milk. The denatured whey proteins will interact with the other milk proteins (caseins) in such a way that the rennet no longer has the normal coagulating effect. This will result in a weaker curd structure and this gives a less good cheese and also a reduced cheese yield. However, the denaturation of the whey proteins is of minor significance if the pasteurization is done at low pasteurization or at even lower temperature. Pasteurization deactivates most of the lipase enzymes that are supposed to break down fats and therefore it is often reintroduce to pasteurized milk to make cheese from it. The denature effect of the whey proteins will however be of insignificant influence if the pasteurization is carried out as

Advantages 1) Kills off health hazardous microorganisms Disadvantages 1) Reduced nutritional value |

Homogenization

Homogenization – or not

When milk is homogenized, it ensures consumers experience the same standard with every carton of milk they buy since homogenization destroys lipid membranes and prevent lipids from forming a layer of cream on the surface which might make the milk less appealing to some. When milk is homogenized, it is forced through a narrow filter that breaks most of the fat globules into particles that are ten times smaller. How flavors develop in cheeses highly depends on the break-down of glycerol and fatty acids in the milk, - an act carried out by enzymes like lipase. Homogenization break the fat globule membranes and make the fat molecules more susceptible for lipase to work on thus, flavors develop faster in cheese made from homogenized milk which can be an advantage sometimes. When making rennet-set cheese, how the texture turns out greatly depend upon what level of homogenization the milk has undergone. Curd made from homogenized milk tends to have less integrity than curd from non-homogenized milk because the lipid membranes are broken. This potentially disrupts the formation of the new protein structure (curd) and the result is a curd with less integrity which however works well when making feta cheese. By experience, we have learned that the gentler processing the milk has been exposed to prior to using it for cheese or yogurt making, the better flavors and texture seem to develop. We therefore prefer to use non-homogenized milk but it is possible to use partly homogenized milk to impact how the flavors develop. Advantages 1) Standardized appearance and taste (?) Disadvantages 1) May induce health consequences |

Cheese milk

Cheese-milkCheese-milk is the milk you use for making cheese. Most milk types are suitable but there are exceptions and some are better than others. Cheese-milk must be fresh and come from healthy animals whether it is from cows, sheep or goats. Animal based cheese milk can never be substituted with plant based milk like soy- rice- or oats milk. You can make Tofu from Soy but that is a completely different process. From a storeFresh store bought milk works fine for cheese making. As fresh milk from a farm has a higher fat content it will therefore often make a better cheese. You may compensate the store bought milk by adding some extra whipping cream to it. Non-homogenized, with a few exceptionsMost cheeses are made from non-homogenized milk, not only for practical reasons to ease the cheese making process but because it optimizes flavor and texture development during the maturation phase. There are however exceptions where some blue mold cheeses are best made with homogenized milk as this promotes fast flavor development. For cheeses like feta cheese you could substitute 10-15% of the non-homogenized milk with homogenized milk. The result is a softer cheese with faster development of flavors. The explanation is that the smaller fat globules present in homogenized milk cause curd to pack more densely and slow the drainage of whey. The higher the content of whey, the softer it becomes. The broken fat globule membranes will make the lipids more accessible for the enzymes to work on and this cause a quicker flavor development in homogenized milk, as mentioned above. You can make cheese entirely from homogenized milk but beware that the curd tends to crumble and have less integrity compared to curd made from non-homogenized milk. On the contrary, curd made from non-homogenized milk is often more structured and easy to work with whereas curd made from homogenized milk can be more challenging and lively due to smaller curd grain size. There is even a risk that some of the small curd grains will flush out along with the whey and leave you with less curd. Having said that, flavors develops nicely in cheese made from homogenized milk and with a bit of practice it is easy to control the somewhat more livelier curd. Note: Skimmed milk and whipping cream are always non-homogenized and you can compose your own non-homogenized cheese milk by mixing the two together. Read our guidance later in this section and learn how to calculate the correct mix. PasteurizedPasteurization makes cheese making easier in the sense that unwanted bacteria have been ridded from the milk and this enables you to control flavor development optimally by only adding wanted species of bacteria. Not high-pasteurizedA standard pasteurization implies a brief heating to 72°C and does not alter the milks ability to curdle and transform in to cheeses whereas high-pasteurization is heat processing above 140°C under pressure and that will alter the proteins in a way that make them unsuitable for cheese making. Use fresh milkWe do not recommend you use anything but fresh milk as cheese-milk. It is not advisable to use milk near its expiry date. Despite pasteurization bacteria still develop even in store bought milk and could potentially ruin the cheese you are trying to make. Always aim to get the best and the freshest milk for cheese making. Fat ContentThe most delicious cheeses are those made from high fat milk but there is nothing stopping you from using low fat milk types to make cheese. The fat content in milk does not affect the initial cheese making process, it only influences the fat content in the cheese. A cheese made from semi-skimmed milk will have reduced fat content compared to a cheese made from whole milk and a cheese made from semi-skimmed milk is normally considered a low-fat cheese whereas cheese made from whole milk is a semi-fat cheese. Fresh milk from farms whether it is from goats, cow or sheep will produce some delicious full-fat cheeses since this milk is naturally high in fats. For semi-soft cheeses like feta and brie, as a rule of thumb the fat percentage usually falls out 7 times higher than it was in the milk. This means if a Feta cheese is made from semi-skimmed milk with 1,5% fat the cheese will have 10,5% fat and a feta cheese made from whole milk with 3,5% fat has 24,5% fat. Since harder cheeses have less water content than softer cheeses like Feta cheese their fat content usually falls out 8-10 higher than what was in the milk it was based on. This means a Danbo cheese made from whole milk (3,5%) has 35% fat. You can compose your own cheese milk by mixing two types of milk with different fat content. Use the formula below to calculate the total fat content when you mix two types of milk with different fat content. We use the following abbreviations:

It follows that: Fat contents in milk of type 1 + Fat content in milk of type 2 Using abbreviations: N1 ∙ F1 + N2 ∙ F2 = ( N1 + N2 ) ∙ FO

Note: The percentage of fat in store bought milk is different in different countries. The following is based on the Danish standards where skimmed milk has 0,1% fat, semi-skimmed milk has 1,5% fat, whole milk has 3,5% fat and whipping cream has 38% fat. If you live in a country with other standards for fat content, you must correct for this in the following. Eksample – A rich Feta cheeseComposing a cheese-milk made from 8 liters of whole milk and ¼ litres whipping cream:

Eksample – A lean Feta cheeseComposing cheese milk for a low fat feta cheese, using 8 litres of semi-skimmed milk with ¼ litres whipping cream: